Medical Power Supply - An Essential Element in Equipment Design

The customer landscape is transforming every passing day. Everyone has become quite stringent in making their decisions. And the recent changes in the US healthcare ecosystem are further creating a profound impact in this industry.

But what led to this change?

Well! The technological advancements in this field were mostly triggered by the growing age of the population and major healthcare reforms. Other trends like the increase in the use of wireless technologies and implantable medical devices are also pushing the healthcare industry to meet the increased density and efficiency goals.

This is why the power ratings must be reviewed correctly. Besides this, a few more critical considerations like the life of the product, thermal issues,load, input voltage, and other key elements impact the design process.

In this article, we'll explore why power design is unique in this field and everything about the emerging new trends.

Decoding The Reasons Behind Unique Power Supply Design

The medical power supply differs from the commercial power supply line for different reasons. Firstly, the designs are based on the safety of the patient since that is a paramount concern. Understandably, exposure to even a tiny electric leakage can drastically impact a patient's health.

This is why the governing bodies allow only an acceptable value of leakage currents (unintentional) in the medical devices. Ideally, it shouldn't be a few hundred microamps.

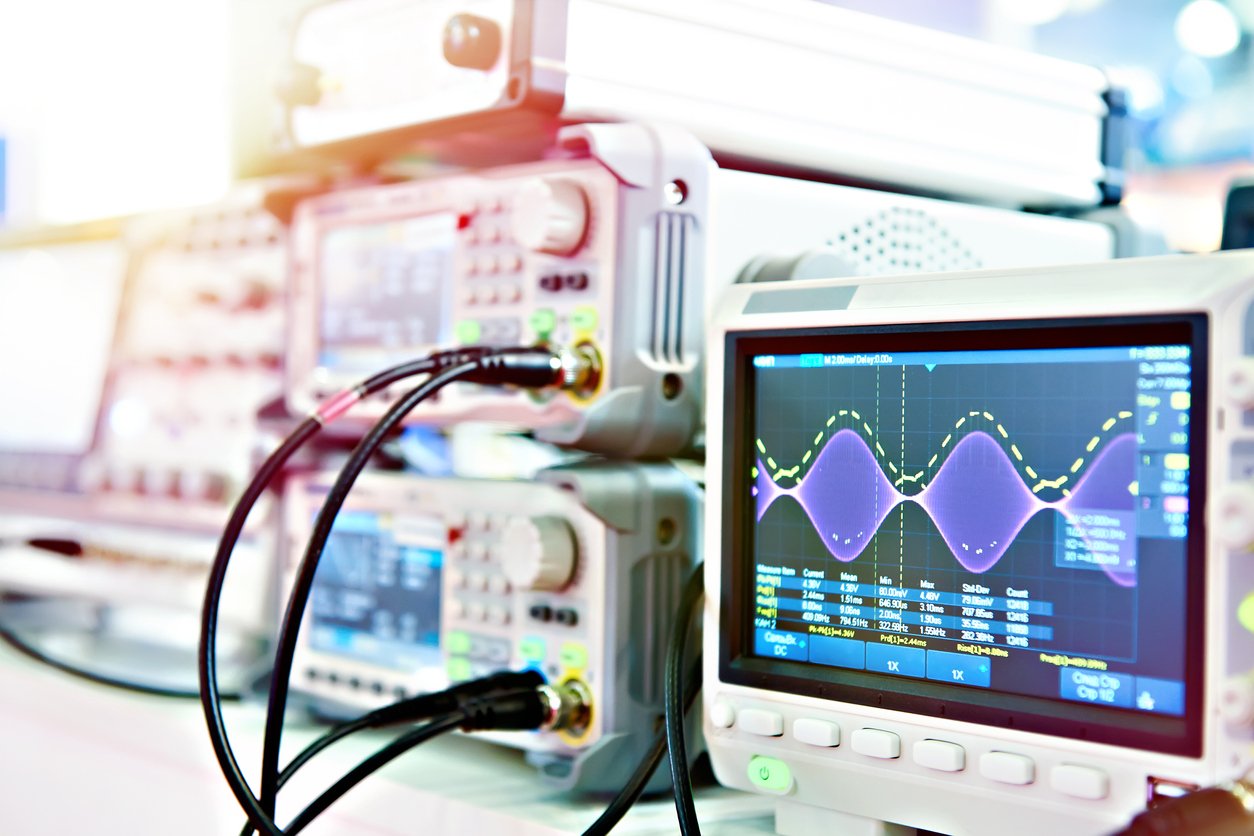

Secondly, the electronic equipment used in the healthcare setting usually requires low-level signals. Such equipment is typically vulnerable to electromagnetic interference, making performance a key concern along with EMC compliance when designing medical power supplies.

Let's find out more about EMC compliance specifications based on the EN61000 standards.

Table 1: EMC compliance standards

According to the standards set by these regulatory bodies, the equipment must meet all the safety and performance requirements. It implies that it must follow IEC 60601-1 3rd Edition for medical devices. However, according to the intent of use, it might have to follow additional standards for EMI/EMC, RoHS compliance, and CE Mark.

Depending on various standards, there are ideally three types of equipment. These include:

- B-rated: It will only contact the patient briefly.

- BF-rated: This type of equipment will have consistent contact with the skin.

- CF-rated: This is most likely to have an internal connection with a patient.

Understanding The Challenges

Many factors contribute to the sustainability of medical-grade power supplies. It includes safety, longer design cycles, and greater life expectancy to support the equipment. This is why the designers need to consider different factors for PSU engineers.

- They must not miss out on the ideal creepage distance/ air clearance. To avoid stray currents harming the patients, medical PSUs require more splendid isolation compared to industrial or commercial PSUs.

- Since the designers need to limit the current from the AC line, this often complicated the transformer design. This is especially the case with CF-rated supplies.

- The designers must create a design that limits the dielectric strength to around 4000 VAC for medical PSU compared to 3000 VAC in industrial or commercial designs.

Any deviance from the set standards might land the healthcare settings in deep trouble since it will directly impact the health of the patient.

Real-World Examples

Medical power supplies have a lot of applications in the healthcare industry. For instance, depending on the required power, isolations, and current required, here are some of the uses of medical PSUs in today's healthcare space.

- They power the dental devices used in the dental clinics.

- They are helpful to power the ophthalmic tools for necessary procedures.

- They are commonly used to power the ultrasound devices.

- They have quite a handy role in powering the operating rooms for carrying out surgical procedures.

- They can also be used for medical ventilators.

For instance, Traco offers a comprehensive selection of both AC/DC and DC/DC solutions for medical applications that fulfill 2X MOPP requirements. It is compliant with the EMC requirements of IEC 60601-1 (4th edition).

Decoding The Techniques That's Enabling Healthcare Companies Improve Medical Power Supplies

There is a rise in the use of Field Effect Transistors (FET) as the new age electronic switches to minimize losses. However, this technique is causing interference. Many modern supply designs are using zero-voltage switching or ZVS to mitigate this issue to avoid any compromise with the power supply.

But that's not all!

Recently, the designs are implementing the use of "digital control technologies." In this, many manufacturers are readily changing the "housekeeping circuits" with microcontrollers-based solutions to avoid any circuit complexities. These are helping the industry to create smaller and better end-products.

For instance, the EFE300M series designed by TDK-Lambda UK engineers are helping to reduce the parts count reduction by 25%, resulting in a 45% smaller and around 56% lighter power supply compared to the products available in the market nowadays.

The best part with these digital supplies is that they are certified per the IEC, EN, UL, CSA- 60601-1 standards. And can even be approved to IEC/EN/UL/CSA 60950-1 for general purposes.

This is why the companies need to select the right vendors to get access to the right supplies.

Wrapping up- Shockproof Solutions For Modern Medical Solutions

The term medical grade might not intrigue the interest of many. But, it has a role to play in providing smooth patient experiences. This is why the medical-grade power supplies are specifically designed to meet the IEC 60601-1 medical equipment safety standards.

But unlike what many presume, safety is not the only factor that needs to be considered. The longer design cycles and design support from the power supply vendor need to be included when opting for the medical PSUs. Moreover, it should have a greater life expectancy.

Here are some of the design considerations when selecting the correct medical supply.

- Power requirements specifications early in the design stage.

- Using standard off-the-shelf medical power supply and consider its configurations before jumping on to the custom design options.

- Keep track of the suppliers' quality system

But make sure to always keep a second option handy. So, tell us, do you know any popular use of medical PSUs that we didn’t include in this post? What is trending in this space?